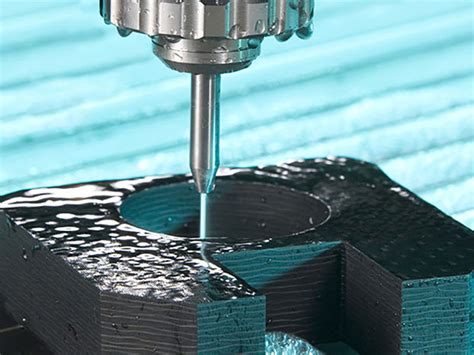

carbon fiber cnc machining The signature requirements for workholding when machining composites are the ability to hold relatively thin components that have a large surface area and that are frequently curved. The roughest approximation of shape comes from the molding . See more Electrical wire: You will need electrical wire of the appropriate gauge and length to connect the wall oven to the power source. Metal junction box: This is used to house the electrical connections and provide a safe enclosure.

0 · water jet cutting carbon fiber

1 · how to cut carbon fibre

2 · end mill for carbon fiber

3 · desktop cnc for carbon fiber

4 · cnc carbon fiber sheets

5 · cnc carbon fiber cutting service

6 · carbon fiber machining near me

7 · carbon fiber cnc cutting

An electrical junction box (also known as a "jbox") is an enclosure housing electrical connections. [1] Junction boxes protect the electrical connections from the weather, as well as protecting people from accidental electric shocks.

water jet cutting carbon fiber

Composites, simply put, are multiple materials with different physical and chemical traits that work together to create a stronger, lighter, or sometimes more flexible product. Composite materials are combined, but never fully fused into one material; so while they do work in tandem, they are separate and distinct . See moreCarbon Fiber Relaxes When Cut One of the key problems with machining composites is that machined holes and pockets will tend to . See more

Diamond Tooling PCD tooling is preferred over carbide to resist the abrasion of composite machining. Image courtesy of Fullerton Tool. One of the first factors that comes up in any consideration of tooling for composite machining is the material’s abrasive . See more

100 amp electric box

The signature requirements for workholding when machining composites are the ability to hold relatively thin components that have a large surface area and that are frequently curved. The roughest approximation of shape comes from the molding . See moreWhether you are using PCD tooling or not, you need Feeds and Speeds designed for your Composite Materials. Our G-Wizard Calculatorcan provide them. To access them, select the . See more Machining carbon fiber promises superior-quality finished components characterized by lightness and rigidity. It allows you to craft unique carbon fiber constituents in line with your specific use requirements. Among different processes, carbon fiber machining is one of the prominent ones for crafting components of various shapes and size. Carbon fiber materials can be processed by Milling, turning, drilling, tapping, and other .

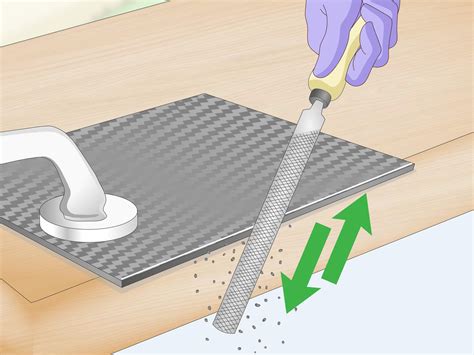

Machining carbon fiber presents several significant challenges, including tool wear and damage, delamination and fiber pullout, dust and health hazards, heat generation and thermal damage, and achieving a desired surface finish and . Carbon fiber surpasses conventional CNC machining materials such as aluminum, steel, wood, or glass. It creates high-performance, durable, and low-weight components. Machining carbon fiber sheets is generally accomplished using a router. However, other standard machining methods are also effective.

FRP (fiber-reinforced plastic) composites are produced from strands of aramid, carbon, glass or other fibrous synthetics. These reinforcements are bound together using some resin, typically a thermoset or thermoplastic .We utilize both 3-axis and 5-axis CNC machining technologies to cut, mill, and shape carbon fibre materials. Our process ensures high accuracy, maintaining the integrity and strength of the carbon fibre.

Machining Carbon Fiber Sheets - Cutting and drilling CFRP easily and precisly with a CNC milling machine. Make clean cutting edges and drill holes.Carbon fiber machining requires more flexibility than working with other materials. As a handmade composite, different solutions present themselves when cutting, milling, tooling, and drilling.Get custom carbon fiber parts within 1 day. 14+ Years of Carbon Fiber Machining Expertise. Free Design and Provide Solutions. No Minimum Order Quantities, ≥1. T1 Samples as Fast As 1 Day. Secondary Finishing. 100% Quality . Carbon Fiber and Composites have special machining challenges. Discover the tips, techniques, and tooling needed for successful machining.

Machining carbon fiber promises superior-quality finished components characterized by lightness and rigidity. It allows you to craft unique carbon fiber constituents in line with your specific use requirements. Among different processes, carbon fiber machining is one of the prominent ones for crafting components of various shapes and size. Carbon fiber materials can be processed by Milling, turning, drilling, tapping, and other machining operations.

Machining carbon fiber presents several significant challenges, including tool wear and damage, delamination and fiber pullout, dust and health hazards, heat generation and thermal damage, and achieving a desired surface finish and precision.

Carbon fiber surpasses conventional CNC machining materials such as aluminum, steel, wood, or glass. It creates high-performance, durable, and low-weight components. Machining carbon fiber sheets is generally accomplished using a router. However, other standard machining methods are also effective.

FRP (fiber-reinforced plastic) composites are produced from strands of aramid, carbon, glass or other fibrous synthetics. These reinforcements are bound together using some resin, typically a thermoset or thermoplastic system. You can also use added ceramic or metal powders as reinforcements.We utilize both 3-axis and 5-axis CNC machining technologies to cut, mill, and shape carbon fibre materials. Our process ensures high accuracy, maintaining the integrity and strength of the carbon fibre.Machining Carbon Fiber Sheets - Cutting and drilling CFRP easily and precisly with a CNC milling machine. Make clean cutting edges and drill holes.Carbon fiber machining requires more flexibility than working with other materials. As a handmade composite, different solutions present themselves when cutting, milling, tooling, and drilling.

Get custom carbon fiber parts within 1 day. 14+ Years of Carbon Fiber Machining Expertise. Free Design and Provide Solutions. No Minimum Order Quantities, ≥1. T1 Samples as Fast As 1 Day. Secondary Finishing. 100% Quality Guaranteed. All uploads are secure and confidential. Carbon Fiber and Composites have special machining challenges. Discover the tips, techniques, and tooling needed for successful machining. Machining carbon fiber promises superior-quality finished components characterized by lightness and rigidity. It allows you to craft unique carbon fiber constituents in line with your specific use requirements.

Among different processes, carbon fiber machining is one of the prominent ones for crafting components of various shapes and size. Carbon fiber materials can be processed by Milling, turning, drilling, tapping, and other machining operations.Machining carbon fiber presents several significant challenges, including tool wear and damage, delamination and fiber pullout, dust and health hazards, heat generation and thermal damage, and achieving a desired surface finish and precision.

Carbon fiber surpasses conventional CNC machining materials such as aluminum, steel, wood, or glass. It creates high-performance, durable, and low-weight components. Machining carbon fiber sheets is generally accomplished using a router. However, other standard machining methods are also effective. FRP (fiber-reinforced plastic) composites are produced from strands of aramid, carbon, glass or other fibrous synthetics. These reinforcements are bound together using some resin, typically a thermoset or thermoplastic system. You can also use added ceramic or metal powders as reinforcements.

We utilize both 3-axis and 5-axis CNC machining technologies to cut, mill, and shape carbon fibre materials. Our process ensures high accuracy, maintaining the integrity and strength of the carbon fibre.Machining Carbon Fiber Sheets - Cutting and drilling CFRP easily and precisly with a CNC milling machine. Make clean cutting edges and drill holes.

Carbon fiber machining requires more flexibility than working with other materials. As a handmade composite, different solutions present themselves when cutting, milling, tooling, and drilling.

10 x 1 1 2 sheet metal screws

Octagon (ceiling) box screws are 8-32. Wall box screws are 6-32. Fan support box screws and ground connection screws are 10-32. Both ceiling and wall box screws are typically about 1-1/4" long, combo head.

carbon fiber cnc machining|cnc carbon fiber sheets